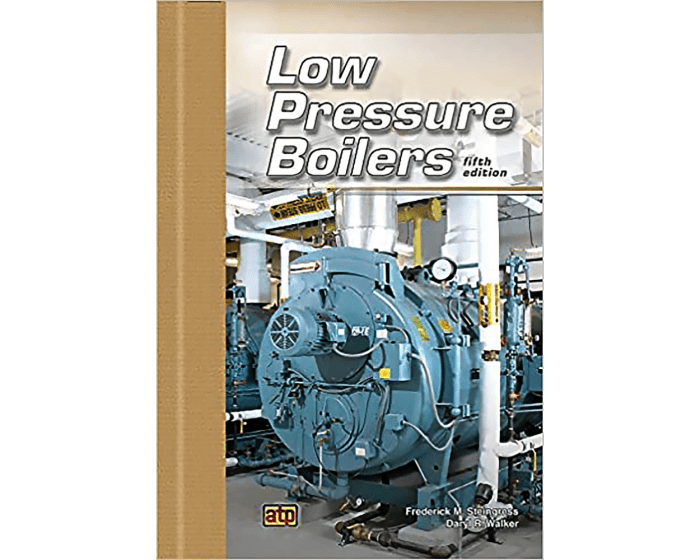

Low pressure boilers 5th edition pdf – Welcome to the definitive guide to low pressure boilers, meticulously crafted in the fifth edition of this esteemed publication. This comprehensive resource delves into the intricacies of low pressure boiler technology, providing a wealth of knowledge for professionals and enthusiasts alike.

From design and construction to operation and maintenance, this guide covers every aspect of low pressure boilers, empowering readers with the expertise to optimize performance, ensure safety, and navigate the latest advancements in the field.

As we embark on this journey, we will explore the fundamental principles governing low pressure boilers, unravel their historical evolution, and examine the diverse applications where they play a pivotal role. With a focus on clarity and precision, this guide presents a comprehensive overview of low pressure boiler technology, empowering readers to harness its potential and mitigate potential risks.

Introduction

Low-pressure boilers are a crucial component in various industries, providing heat and steam for essential processes. Their significance lies in their ability to generate steam at relatively low pressures, typically below 15 pounds per square inch (psi). This steam is utilized for heating, sterilization, and power generation, among other applications.The

history of low-pressure boiler technology dates back to the early 19th century, with the invention of the first steam engine by Thomas Savery. Since then, advancements in boiler design and materials have significantly improved their efficiency and safety. Today, low-pressure boilers are widely used in industries such as food processing, pharmaceuticals, textiles, and chemical manufacturing.

Design and Construction

Low-pressure boilers are designed and constructed to operate at pressures below 15 pounds per square inch (psi). They are commonly used in residential and commercial buildings for heating and hot water supply. There are several types of low-pressure boilers, each with its own specific applications and design features.

Types of Low-Pressure Boilers

The most common types of low-pressure boilers include:

- Cast iron boilers:These boilers are made of cast iron and are known for their durability and longevity. They are typically used in larger buildings and can be either floor-mounted or wall-mounted.

- Steel boilers:These boilers are made of steel and are lighter and more compact than cast iron boilers. They are often used in smaller buildings and can be either floor-mounted or wall-mounted.

- Condensing boilers:These boilers are designed to capture and utilize the heat from the exhaust gases, which makes them more energy-efficient than traditional boilers. They are typically used in larger buildings and can be either floor-mounted or wall-mounted.

Key Components and Materials

The key components of a low-pressure boiler include the boiler vessel, the burner, the heat exchanger, and the controls. The boiler vessel is the main part of the boiler and is where the water is heated. The burner is responsible for igniting the fuel and generating heat.

The heat exchanger transfers the heat from the burner to the water. The controls regulate the operation of the boiler and ensure that it operates safely.

The materials used in the construction of low-pressure boilers include steel, cast iron, and copper. Steel is used for the boiler vessel, burner, and heat exchanger. Cast iron is used for the boiler vessel and burner. Copper is used for the heat exchanger.

Design Principles and Safety Features

Low-pressure boilers are designed with several safety features to prevent accidents. These features include:

- Pressure relief valve:This valve releases pressure from the boiler if it exceeds a safe level.

- Temperature limit switch:This switch shuts off the burner if the water temperature exceeds a safe level.

- Low water cutoff:This device shuts off the burner if the water level in the boiler falls below a safe level.

In addition to these safety features, low-pressure boilers are also designed to be durable and reliable. They are typically made of high-quality materials and are tested to ensure that they meet all safety standards.

Operation and Maintenance

Operation and maintenance of low-pressure boilers are critical for efficient and safe operation. Understanding the principles of operation, following best practices, and implementing proper troubleshooting and maintenance procedures are essential for optimal performance and longevity of the boiler system.

Principles of Operation

Low-pressure boilers operate on the principle of fuel combustion to generate heat, which is transferred to water to produce steam. The fuel, typically natural gas or oil, is burned in a combustion chamber, releasing heat that raises the temperature of the water in the boiler.

The heated water turns into steam, which is then used for various applications, such as heating, power generation, or industrial processes.

Best Practices for Operation and Maintenance

- Regular Inspections:Conduct routine inspections of the boiler and its components to identify any potential issues or signs of wear and tear.

- Water Treatment:Implement proper water treatment practices to prevent scale formation, corrosion, and other water-related problems.

- Fuel Efficiency:Optimize fuel combustion and heat transfer to maximize efficiency and reduce operating costs.

- Safety Protocols:Establish and follow safety protocols, including regular safety checks, proper handling of fuel and steam, and emergency procedures.

- Record Keeping:Maintain accurate records of inspections, maintenance activities, and any incidents or repairs to ensure traceability and compliance with regulations.

Troubleshooting and Maintenance Procedures

Common troubleshooting techniques for low-pressure boilers include:

- Low Steam Pressure:Check fuel supply, burner operation, and water level.

- Leaking Boiler:Inspect for cracks, corrosion, or loose fittings.

- Overheating:Check water level, circulation pump operation, and fuel supply.

Regular maintenance procedures include:

- Cleaning and Inspection:Clean the boiler and its components to remove soot, scale, and other debris.

- Tube Inspection:Inspect boiler tubes for corrosion, erosion, or blockages.

- Safety Valve Testing:Test safety valves to ensure proper operation and prevent over-pressurization.

- Hydrostatic Testing:Perform hydrostatic testing to check for leaks and ensure the integrity of the boiler.

Performance and Efficiency

The performance and efficiency of low-pressure boilers are crucial factors in determining their overall effectiveness and environmental impact. Several factors influence boiler performance, including design, construction, operation, and maintenance practices.

Measuring boiler efficiency involves determining the ratio of heat output to heat input. Methods for measuring efficiency include the direct method, indirect method, and heat loss method. Improving boiler efficiency can be achieved through measures such as optimizing combustion, reducing heat losses, and implementing energy management systems.

Environmental Impact

Low-pressure boilers can have an environmental impact due to the emission of pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. Strategies for reducing emissions include using low-NOx burners, installing flue gas desulfurization systems, and adopting fuel switching techniques.

Applications and Case Studies: Low Pressure Boilers 5th Edition Pdf

Low-pressure boilers find diverse applications across industries, providing efficient and reliable heat generation. Their compact size, operational flexibility, and cost-effectiveness make them suitable for various heating needs.

Case studies demonstrate the benefits and challenges of low-pressure boilers in specific industries. These studies highlight the boilers’ ability to meet heating demands while optimizing energy consumption and minimizing environmental impact.

Industrial Applications

- Food Processing:Low-pressure boilers provide steam for sterilization, cooking, and cleaning processes in food production facilities.

- Textile Manufacturing:Steam from low-pressure boilers is used for fabric dyeing, finishing, and drying in textile mills.

- Paper Production:Low-pressure boilers generate steam for paper drying, pulping, and coating processes.

Commercial Applications, Low pressure boilers 5th edition pdf

- District Heating:Low-pressure boilers can be used in district heating systems to provide hot water or steam to multiple buildings.

- Laundries:Steam from low-pressure boilers is used for washing, drying, and ironing in commercial laundries.

- Hospitals:Low-pressure boilers provide steam for sterilization, humidification, and heating in healthcare facilities.

Emerging Technologies and Industries

Low-pressure boilers have potential applications in emerging technologies and industries:

- Renewable Energy Integration:Low-pressure boilers can be integrated with renewable energy sources, such as solar or geothermal, to provide backup heating or reduce fossil fuel consumption.

- Biofuel Production:Low-pressure boilers can generate steam for biofuel production processes, reducing the environmental impact of transportation fuels.

- Waste Heat Recovery:Low-pressure boilers can be used to recover waste heat from industrial processes, improving overall energy efficiency.

Safety and Regulations

Low-pressure boilers are subject to stringent safety regulations and standards to ensure their safe design, installation, and operation. Adhering to these protocols is paramount to prevent accidents and safeguard personnel and property.

Regular inspections and maintenance are crucial for ensuring boiler safety. Neglecting these measures can lead to equipment failures, energy inefficiencies, and potential hazards.

Consequences of Neglecting Safety Measures

- Boiler explosions, causing injuries or fatalities

- Property damage and financial losses

- Environmental pollution from boiler leaks or malfunctions

- Legal liability for accidents or injuries

Quick FAQs

What are the key safety considerations for low pressure boilers?

Adhering to safety regulations, conducting regular inspections, and implementing proper maintenance procedures are paramount to ensure the safe operation of low pressure boilers. Neglecting safety measures can lead to catastrophic consequences, including explosions, injuries, and environmental damage.

How can I improve the efficiency of my low pressure boiler?

Optimizing boiler efficiency involves regular maintenance, proper insulation, and monitoring of key performance indicators. Employing energy-efficient technologies, such as economizers and variable speed drives, can further enhance efficiency and reduce operating costs.

What are the common applications of low pressure boilers?

Low pressure boilers find widespread use in various industries, including food processing, healthcare, manufacturing, and residential heating. They are particularly suitable for applications requiring steam or hot water at relatively low pressures, such as space heating, domestic hot water supply, and process heating.